Future of Concrete

SYNTHASH, a concrete admixture, uses advanced 21st Century Nano Technology to provide multiple benefits that cover significant issues affecting the Concrete Industry, please view our product comparison chart.

SYNTHASH, a concrete admixture, uses advanced 21st Century Nano Technology to provide multiple benefits that cover significant issues affecting the Concrete Industry, please view our product comparison chart.

Dynamic Synthash

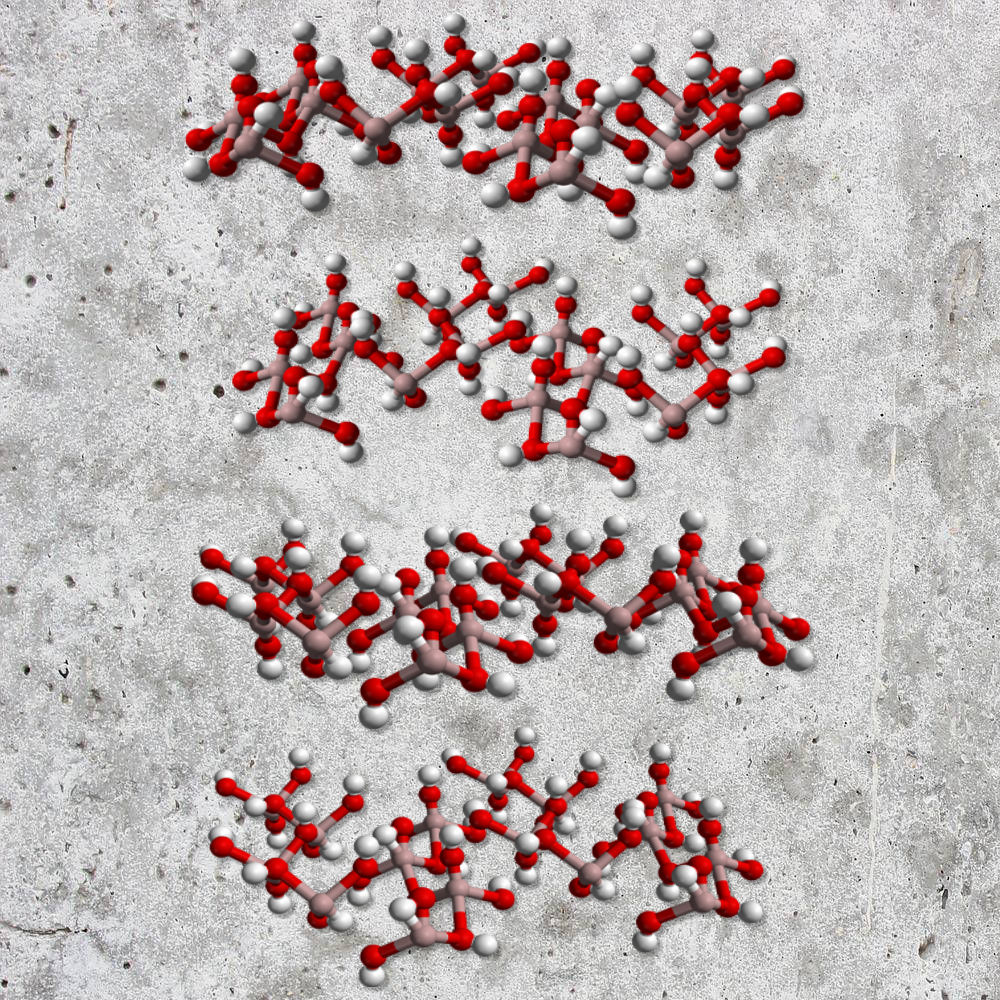

The four atomic layers of the ceramic structure complete a 180º horizontal rotation and slight vertical displacement of the subsequent layer relative to the parent layer. This inter-digitation of ceramic atomic layers provides additional strength and more surface area (due to increased ceramic units within the same space), increasing the cement's tensile strength.

Synthash is a non-chemical green formulation that helps reduce exposure to other harsh chemicals used in concrete mixes—created to be safe for the environment.

Synthash is shown to increase the PSI of cured concrete by 22-32% providing a much stronger substrate and reduce the cost of using superplasticizers.

Synthash allows a higher workability with lower slump using less water due to the ionic charge to the mix with the use of nano-clays, which equates to stronger concrete mixtures.

Synthash creates a molecular bonding of the materials used in the concrete mix to reduce porosity, which produces a much more denser concrete that limits water intrusion.

Synthash is the best pumping agent on the market today, the ionic charge creates a non-stick surface and increases the flow of concrete to hoses and pumps.

Synthash when wet will not bond to plastic, wood or metal, which makes for easy cleanups on forms and molds.

The strong ionic emulsion and the induced nucleation of the cement particle by the Mesopouric Inorganic Polymer serves to maintain intra-molecular tension during the initial set and cure period. This nucleation is enhanced by other nano-ceramics that excite water molecules, creating a more efficient hydration of the cement particles. This process also results in faster set times (once exposed to environmental forces) and a general resistance to early age shrinkage cracking due to the lowered water content (reduced initial (volume) and the increased initial concrete density created by the more efficient “stacking effect” created by the Synthash.

The mixed ceramics within the Synthash formulation interact to improve compression, tensile and flexion cooperatively. There are three major interactions that cause these strength increases: (1) the Mesopouric Inorganic Polymer suspends, ionicly bonds and sequesters organic or inorganic molecules to create tensile and flexion within the concrete’s mass (i.e., the MIP is a coil-shaped inorganic polymer that acts as a cross-linker and plasticizer). (2) Synthash ceramics form a polymerizing ceramic lattice within the concrete (after an estimated 60 days). (3) The Synthash creates atomic-scale bonding between aggregate and cement particles (hydrogen, Van Der Waals, and ionic bonds).

The Synthash Formula is exceptionally statically charged and will act as an ionic emulsifier within the concrete matrix. The aggregates and fines will be evenly suspended in solution based on their ionic charge and relationship with other charged atoms in the vicinity. This affect will increase the workability of the concrete, creating a custard-like rheology. This ionic suspension, together with the Synthash induced nucleation phenomenon, leads to a superior finish-ability, lower porosity and improved surface density.

The Nano-Clays™ within the Synthash matrix, including the MIP, are a combination of ceramics that act cooperatively. The MIP contains pores that are inter-digitally stacked by 180 degrees. This initially allows for cement particle input into these pores. Once in the pores, the particles are now suspended not by the aqueous solution but by the ceramic-polymer matrix of the Nano- Clays. Thus, the MIP acts as a nucleating agent, while other ceramic molecules attract water toward the now ionicly suspended cement particle to drive the curing process (hydration) forward. Further, the MIP molecule is shaped like a corkscrew, thus, the more the curing process is driving forward the more the Synthash-concrete hybrid composite “tightens down” around the MIP (like tightening the lid of a jar), thus densifying the cement. This tightening process at the molecular level also begins to drive excess water out of the ceramic-concrete composite at the macroscopic level accelerating both the set rate and cure time when exposed to environmental factors (wind, solar).

As stated above, the squeezing effect caused by the nucleation of the mass by the Synthash, specifically by the mesoporous inorganic polymer (MIP), causes the concrete mass to contract into an optimized denser pattern; all particulates basically begin to pull inwards in relation to the ironically charges surrounding them. This squeezes the water out, and then eliminates the avenues, or micro-fissures, that water used to exit the concrete. These avenues traditionally allow Chloride ions to enter and penetrate the concrete, oxidizing the rebar. Experimental results show this water-leaving morphological effect is substantially reduced or eliminated by the Synthash. Further, the ceramic polymer formed by the natural polymerization of the MIP molecule and other ceramics, increasingly makes the concrete less porous and more waterproof over time. The overall reduction in porosity directly relates to resistance to freeze-thaw damage. Also, this increased density together with the increased electrochemical stability of the concrete composite will resist carbonation at the surface, again leading to increased durability.

Pervious (zero fines) cement systems are become increasingly popular due to the desire to create better surface water management. This system is held together at the intersection between aggregates’ surfaces, giving the cement “glue” greatly reduced surface area with which to hold the aggregate. This aggregate intersection is therefore more vulnerable to breakage by compression and freeze-thaw damage. Accordingly, the ability of the Synthash is to create additional bonding at the molecular level, while adding increased tensile and elasticity to the cement system, enhances the durability of the surface-to-surface cementing of the pervious concrete’s aggregate. Synthash modified cements will also have less void space for water to collect and freeze-fracture the concrete. The ability of the Synthash to resist ice formation and to cause water to evaporate at an accelerated rate, also add to the durability of the pervious concrete system.

ASTM International, formerly known as American Society for Testing and Materials, is an international standards organization that develops and publishes voluntary consensus technical standards for a wide range of materials, products, systems, and services. And Synthash has been rigorously tested by these standards.

420 US HWY 1, STE 20 North Palm Beach, FL, 33408

1014, Aspin Commercial Tower, Sheikh Zayed Rd. Dubai, United Arab Emirates

9:00am - 5:00pm CST USA

8:00am - 7:00pm GST UAE